THOR 303

THOR 303 DUAL SPARK

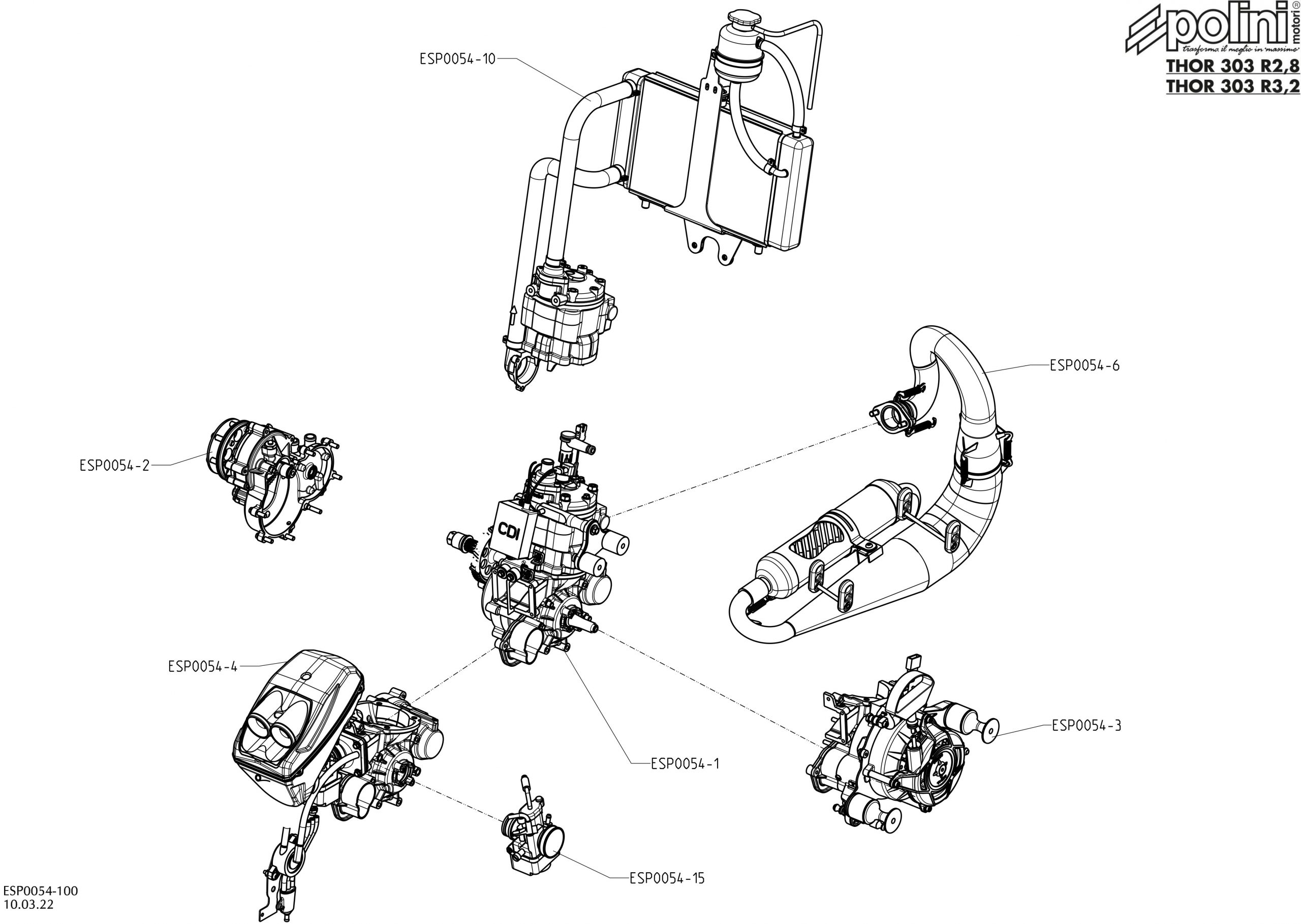

| Polini Engine | 2 stroke monocylinder |

| Cooling | Liquid cooled |

| Bore for stroke | 76 x 62 |

| Displacement | 281 cm3 |

| Power | 38 HP at 8000 rpm |

| *Max thrust | 120 Kg with Ø 160 cm propeller |

| R.P.M. max | 8.400 |

| Cylinder | Aluminum with Gilnisil coating |

| Compression ratio | 11,2:1 |

| Piston | Two trapezoidal chromium plated rings |

| Intake | Reed valve in the crankcase |

| Carburetor | Dell’Orto VHST 28mm |

| Air filter | Air box |

| Ignition | Electronic CDI with adj. advance |

| Battery charger prearrangement | Output power 40 W at 5500 RPM |

| Spark plug hood | 5k Ω resistance |

| **Fuel type | E5 petrol or LL AV GAS-al with 2,5% synthetic oil 100% |

| *Consumption | 3 Lh 30 Kg a of static thrust |

| Gear reduction unit | Helicoidal teeth in oil bath with 2,8 or 3,2 reduction ratio |

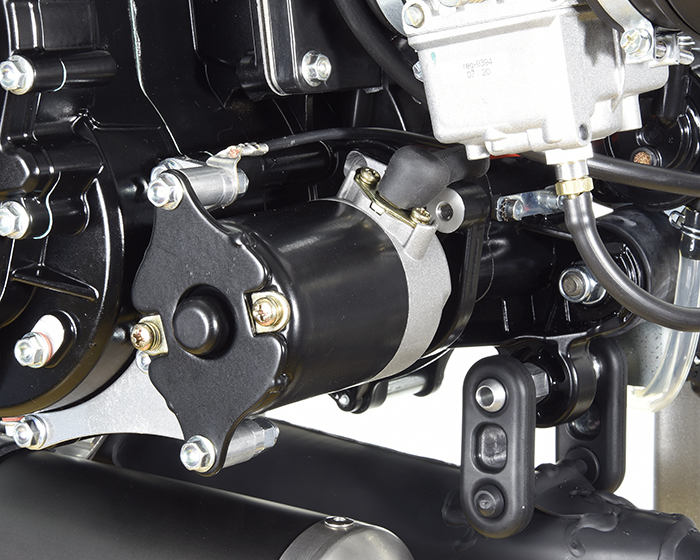

| Starter | Flash Starter – (Electric starter -optional) |

| Clutch | Centrifugal in oil bath |

| Muffler | Expansion with aluminum silencer |

| Engine weight | Starting from Kg 20,5 (manual starter model +radiator) |

| Propeller rotation | Clockwise |

*The values have been detected on the sea level at standard atmosphere. The thrust and consumption values may vary according to the air temperature and density.

**E5 means the petrol type that can be used. E5= unleaded petrol 95 octanes up to 5% of ethanol. This symbol is shown on all the petrol pumps in Europe.

This is the engine of the Thor family with the biggest displacement with cylinder, crankshaft, carburetor, air box, CDI and exhaust system completely redesigned to grant better performance and flight safety.

With 38hp at 8000 rpm, Thor 303 offers 120 kg of static thrust with a propeller of 160cm*

The consumption is only of 3 liters per hour at 4500 rpm, that corresponds to 30 kg of static thrust, medium range at level flight.

Thor 303 is available in 3 versions:

Thor 303 with Manual “Flash starter”

Thor 303 with electric starter+ Manual “Flash starter”

Thor 303 Dual Spark

Dual Spark nine has been designed to satisfy the highest aeronautic safety standards. It is supplied with electric starter+ Manual “Flash starter” and it is equipped with 2 CDI and 2 independent and redundant ignitions.

Flight Safety

Thor 303 is the result of 3 years of hard work, design and tests both on the Polini modern testing benches and of our professional Italian and international pilots. An accurate work that doesn’t stop after the production, when every single engine is tested and inspected before delivering it.

The Cylinder

The cylinder has been designed and manufactured for the specific aeronautic use by exploiting the best modern technology. The real displacement is 281cc with 76mm bore and 62mm stroke. The cylinder has 5 transfers to give precise and performance and at all rpm , giving smooth and powerful output able to offer more than 120kg of static thrust with 160cm* propeller installed.

The head is designed with a special combustion chamber that make the flame front faster.

The Muffler

From the experience achieved during the years, the new 2 stroke exhaust system has been designed to enhance the performance and to grant low noise. Compact and light, it was subjected to long tests and research to find the perfect union between expansion and gas flows: the result is a muffler that assures a stable and progressive power output at all the rpm.

The installation and the spherical coupling system allow free movements, eliminating any vibrations thus extending the life of the muffler.

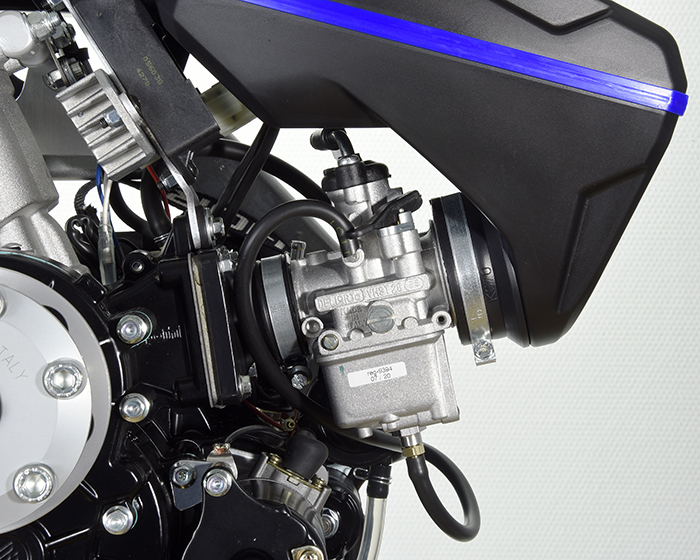

The Carburetor

The new Thor303 is equipped with Dell’Orto VHST 28mm carburetor.

The carburetor technology makes the engine less sensible to environmental changes connected to atmospheric pressure, humidity and air pressure, thus granting more stability to latitude/longitude and height variations and minimizing the setting sections.

This carburetor can be equipped with the Polini starter control, which is essential to start the engine safely.

Thanks to all these advantages, together with the different settings options, Dell’orto carburetor satisfies all the pilots needs, thanks to the high precision levels, smoothness and power output.

To carry it: the carburetor is equipped with a proper valve to drain all the fuel it contains, to position it horizontally to avoid fuel leakage.

Air box

Thor 303 is equipped with an air filter which is the result of a deep fluid dynamic study that has the aim to optimize the air speed inside it to grant the perfect pressure to feed the carburetor at every rpm. By reproducing a S circuit that stabilizes the turbulences, the new filter lets a linear, sweet and constant output. It is possible to open and check it; inside there is a supporting frame for its filtering carpet made of polyurethane foam with open cells of 30 PPI (holes per inch): this supporting frame has been designed to have a fixing able to prevent the carpet from moving or collapsing on it. Furthermore the filter cage can be opened in a half through two screws to be easier to replace it during standard servicing.

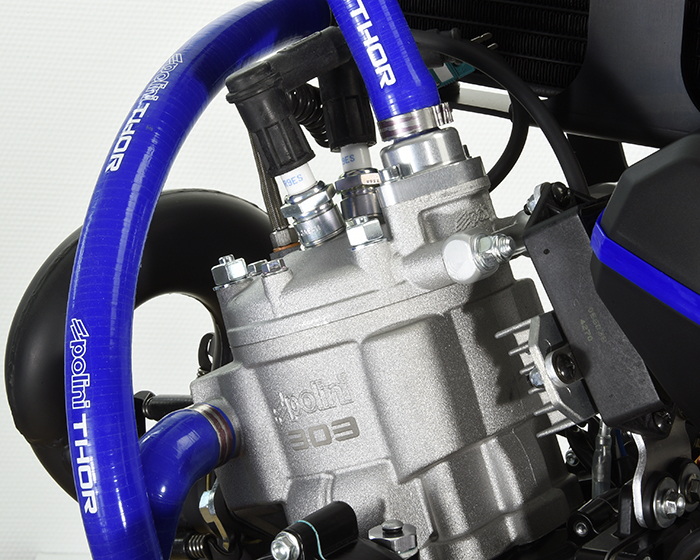

Cooling system and water pump

Thor 303 cooling is granted by a 18-component compact radiator with reduced size of 355x200mm with expansion tank.

The cap is provided with a 1,4 bar valve to let the system self-regulate the expansion of the liquid inside it without weighting on other parts. Liquid flow is made by a specific mechanic pump of 30mm positioned on the countershaft. This system keeps the cylinder temperature under control in all the applications, thus granting a longer use of the engine and avoids overheating. With a great care to the design the blue silicone pre-shaped pipes, customized “Polini Thor” grant longer life.

The engine is also equipped with a thermostat to avid temperature goes under 60°

Reed Valve

The engine is equipped with reed valve with direct intake in the engine crankcase. The reed valve, designed by Polini R&D department, has been conceived to optimize the performance. This result can be achieved thanks to the use of 6 carbon fiber reeds with calibrated elasticity to react uniformly at all RPM.

Engine Crankcase

Thor 303 crankcases are die cast in aluminum with high siliceous content: thanks to this alloy and to the production process during all the phases (starting from the foundry, passing through the painting, to the mechanical working on sophisticated CNC machines), it is possible to achieve stable and long lasting mechanical performance matched to a reduced weight.

The design of the crankcases has been optimized to be essential and reinforced where more stressed, increasing the TBO up to 400 hours.

Crankshaft

The choose of the best steels and thermic treatment together with a perfect centering, eliminates vibrations due to unbalancing that during the time should drive to premature worn or structural failure.

Thanks to the CNC machines and to the use of measuring tools of last generation, the dimensions stay inside pre-arranged tolerances. Moreover the bearings are of very high quality and are placed on the coil and crankcase.

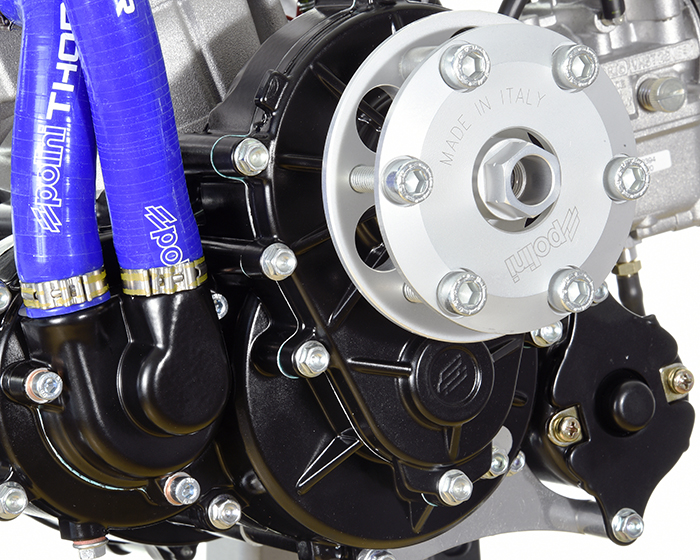

Countershaft, gear and clutch

In the front crankcase there is the housing of the centrifugal clutch system, the mechanical reduction and the balancing countershaft, all in oil bath.

The centrifugal clutch allows the propeller to be static when the engine is to minimum rpm and maximizes the safety for the pilot in the pre-flight stages.

The new Thor 303 engine is supplied with two different propeller reduction: 2.8 (recommended for 140cm propellers) and 3.2 ( for propellers bigger than 140cm).

The mechanical gear has helicoidal teeth: this system inverts the revolution way of the propeller respect to the crankshaft, softening the overturning torque.

The balancing shaft reduces the vibrations coming from the unbalancing generated by the piston swinging that, passing through the BDC and TDC, moves the mass at every single rotation circle of the engine, thus granting the maximum flying comfort.

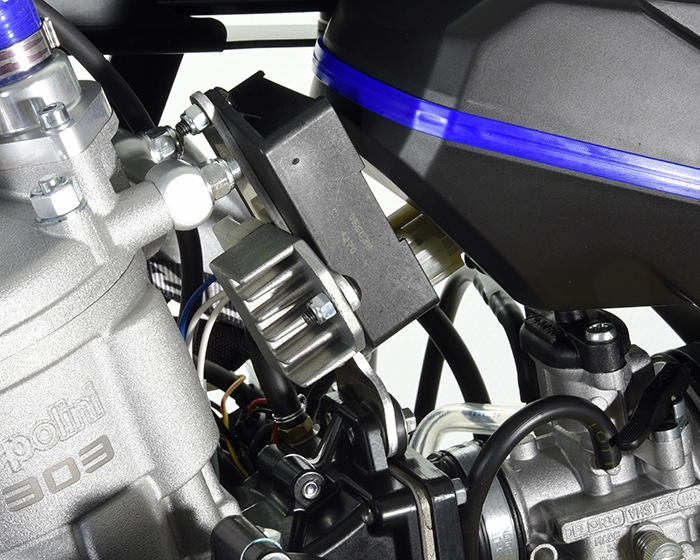

Electronic Ignition

The capacitive electronic ignition is controlled by a CDI designed for Thor 303 engine. The CDI automatically adjusts the engine advance depending on the rpm., thus grating an easy start and smooth and ready power output.

Flash starter

Thor 303 is equipped with the latest version of the well known Flash starter, system that grants an easy engine starter.

The critical points of the last version of the flash starter have been reinforced, improving the centering to extend its life. An ergonomic handle lets a safer and stable grip during the starting.

THOR 303 DUAL SPARK

This model has two completely independent and redundant ignition systems, managed by 2 CDI, 2 stators, 2 coils and 2 spark plugs that grant better performance and more safety when using it.

The standard capacitive electronic ignition is matched to a second ignition that read the signal through a dedicated pick-up and send it to the secondary CDI, that controls coil and secondary spark plugs.

Fixing System

Polini Motori has decided to maintain the same fixing points on all Thor engines. Manufacturers may produce a frame that can house the entire range of Thor engines, thus reducing significantly production costs and timing.

Pilots can replace the Thor engine without replacing or modifying the frame.

As for the entire range of Thor engine, Thor 303 too is sold together with all the parts necessary to install it, already assembled and ready to be assembled on the frame very easily. For the model with electric starter of DS the engine is supplied with electric wiring and plug and play battery.

Use

Considering the power of the Thor 303 engine, it finds its highest expression when installed install it on single or be-place trike, delta trike, 3-axle or U.A.V (unnamed aerial vehicle).

The installation on single-seat paramotor is recommend to expert pilots only and for slalom competitions.